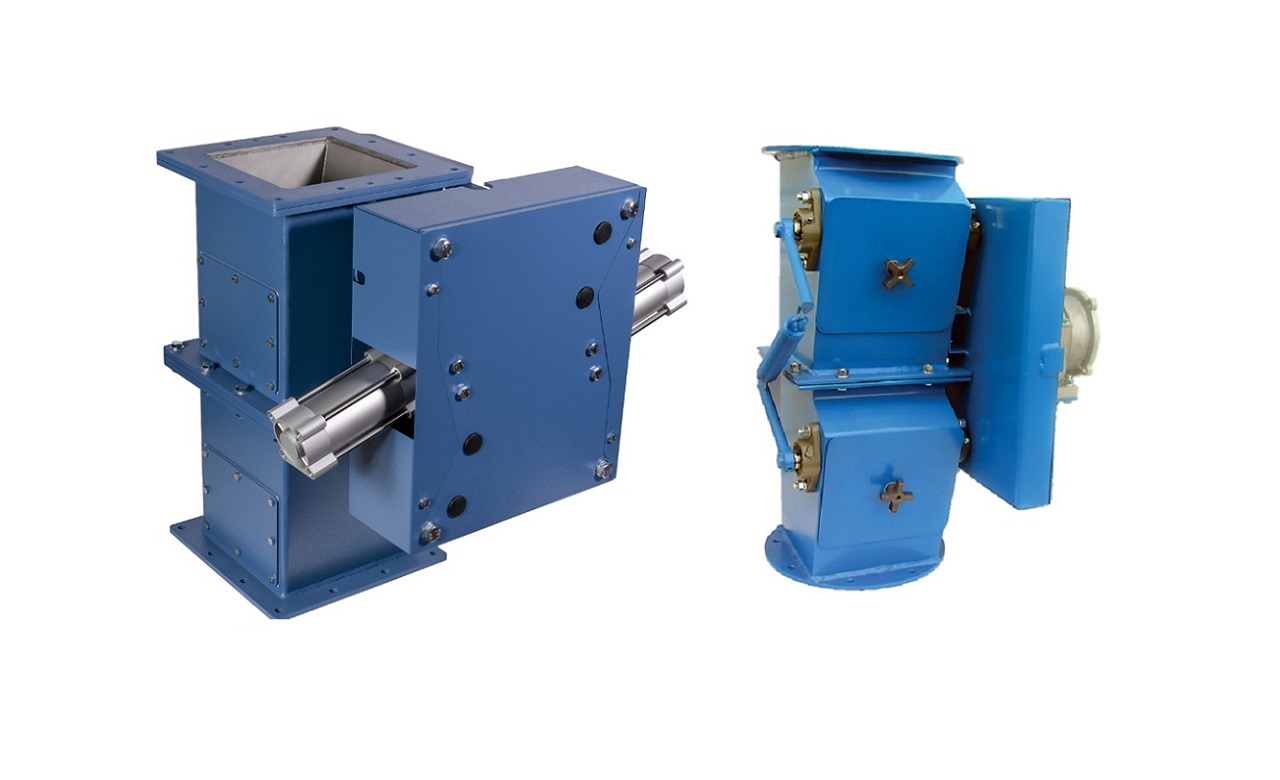

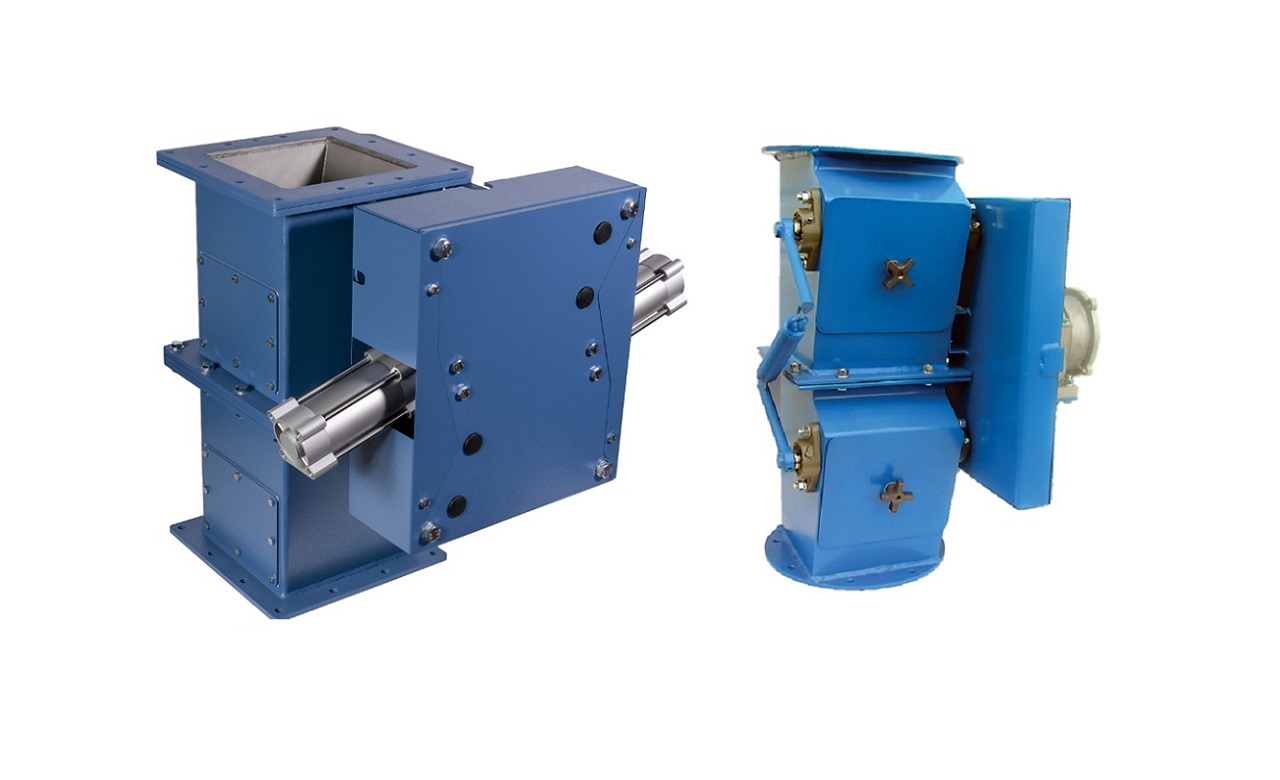

DeGATECH dump valve (also known as a double dump valve, flat gate valve, or double flap gate valve) controls the rate of material flow through a system more efficiently than a rotary valve. Because there are two gates, one of which is always closed, the pressure drop from inlet to outlet is always maintained. A dump valve endures much less wear and tear than a regular rotary valve, making it last longer and keeping maintenance costs down.

Our dump valves are available with pneumatic, gravity and electric operators. These valves are widely used in the following industries: cement, fly ash, iron ore, paper, and bulk powders.

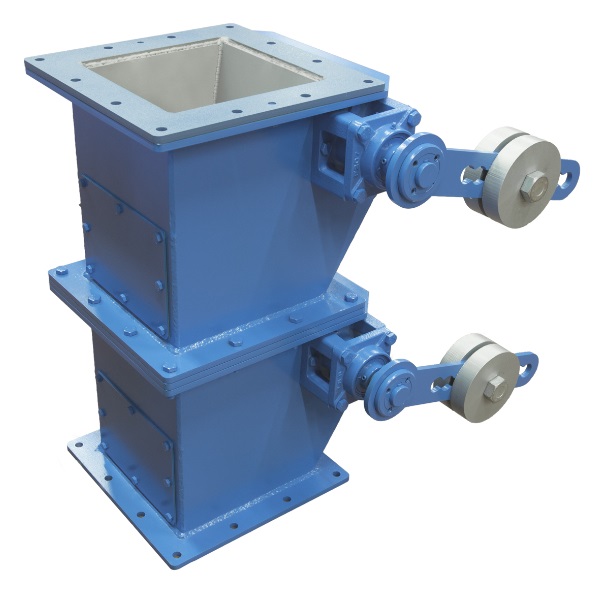

SLIDE GATE VALVE

DeGATECH offers a wide variety of slide gates to meet your dust collection and feeder needs. These valves are operated manually & pneumatically. From simple, manual slide gates that temporarily seal off your hopper while you change your dust collector drum, to automated electric or pneumatically controlled feeder applications, we can deliver the right option for you. With an aim to fulfill varied requirements of our valued clients, we are engaged in offering Pneumatic Slide Gates. At our unit, our professionals manufacture the gates by adhering to industry norms. They also make sure to use quality materials and approved components for manufacturing the gates. Once the gates are ready for operation, our engineers ensure by opting strict quality checks so that the gates offer reliability and high performance to the clients. Furthermore, clients can opt for custom design and compact design according to business requirements.

FEATURES:

– Robust construction

– Easy operation

– Noise less performance

Models are available:

– Pneumatic Air Operation

– Manual operation

All Welded Construction – Slide gate frames are designed and constructed as one weldment to provide maximum rigidity for heavy industrial applications in round and square openings. Heavy Duty slide Plate – Slide plates are made from 3/16” up to 1/2” thick solid carbon or stainless steel to withstand product pressure and head load. The corners of the slide plate are beveled to prevent binding when opening and closing the gate. The pneumatic cylinder is directly attached to the slide plate for a compact and economical design.

Benefitss Compact Design – The DeGATECH pneumatic slide gate’s compact design allows it to fit in almost any space. The compact, modular design allows for the integration of solenoids, filter/regulators, and position switches. Versatile and rugged – Custom designed pneumatic slide gates can be built to fit any application. The slide gate frame and slide plate can be fabricated from a wide variety of materials and thicknesses. Inlet and discharge transitions can be adapted to fit any opening configuration. Large diameter bore cylinders can be utilized for head loads and tough applications. This versatility allows the design to be custom tailored to fit any application and/or design conditions.

DeGATECH Pneumatic slide Gate standard Construction Gate Size Inside Square Dimension Body Thickness Blade Thickness

Please contact the DeGATECH pneumatic sales and engineering staff with any of your unique slide gate and pneumatic applications today. We can advice you appropriate solutions for your applications.

OUR CARTRIDGE FILTERS

DeGATECH also manufactures and supplies custom and in stock Cartridge filters for any type of Cartridge Dust Collector. Our dust collector Filter Cartridges are available in many top and bottom configurations and a variety of filter media options to handle the dust load and dust properties of your work environment.